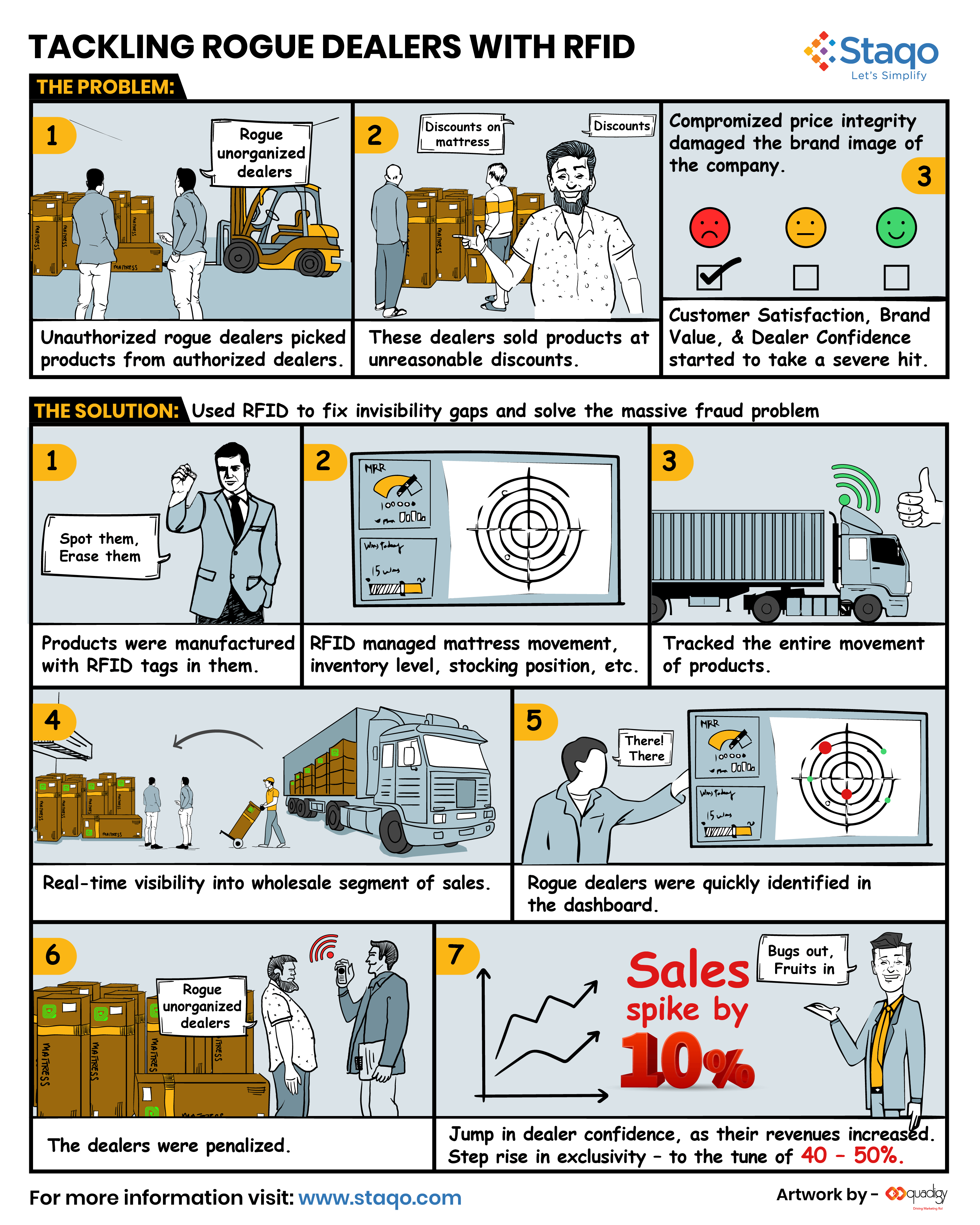

Mala fide dealers ruin sales, brand value and goodwill, only because they are slippery and under the company’s radar. What if something could kill this unfair advantage?

It takes time to grow into a tree. That vast footprint of factories, suppliers and retail stores or that brand name one swears by – that is never built easily.

That’s why it really hurts when termites chew a tree from the inside. The damage goes beyond the bark.

In the case of this manufacturing conglomerate, these termites came in the form of some rogue dealers. If you think it was a tiny problem, yes, the size may have been tiny, but not the loss that was inflicted.

When Off-chain Dealers Spoil Brand Image

For any product chain to work smoothly and profitably, it is important to have the right network of partners, dealers and retail points forming a proper flow up to the very last mile. But what about the dark spots and tunnels here?

As this mattress-major suffered first-hand, a rogue dealer does more than marking down the price of a product. These unauthorized dealers started becoming a pain point for that very reason.

They used to pick branded products from authorised dealers so that they could add a good brand to their unorganised store set-ups. Next they would start selling these products at unreasonable discounts. Whenever a customer enquired about the price difference, they would say – ‘I will not charge you for expensive showrooms the way branded stores do’.

Bit by bit, such bad-mouthing would ruin the customer’s confidence in the price integrity and brand image of the company’s mattress. The company started realising this invisible, but, deep damage that was trickling into its customer loyalty. Now users were comparing mattresses not on the terms of quality or brands but on spur-of-the-moment discounts. This was undermining price stability as well as dealer confidence in the supply chain. Also, sales campaigns and advertising endeavours were not able to reach this tertiary layer. Customer satisfaction and brand image – both were taking a severe blow.

What was helping these rogue elements was the sheer lack of visibility and real-time information about the SKU’s movement. This is something that can cost a company not just delays or defects but a big dent in customer experience as the last mile of the chain was away from the company’s eyesight.

As much as 3 to 4 per cent of the market – this rogue segment was now beeping loud on the company’s orbit. The company had to act fast and weed these fraud elements out. Because if any more delay or oversight was allowed, the fraud could hairball into serious and long-lasting impact. The question was how to spot and stop these rogue dealers – specially in a partner network as sprawled and as on-the-go as this company’s supply chain?

The answer was RFID.

Spot them, Erase them

Staqo’ team suggested how and where RFID could fix invisibility gaps. This was a good time to explore these capabilities for solving the fraud problem.

The team inserted RFID Tag in each mattress/product that is manufactured in the factory. The mattress movement, inventory levels, stocking position etc. – was managed by RFID Tags. RFID kept a tough grip on the movements – from factory to warehouse, to distributor, to dealer, to retailer to Customer – without blinking an eye.

Now the company could trace where a mattress was made, where it went and where it was sold until the very last authentic point of chain. This helped it attain real-time visibility into the wholesale segment of sales where rogue dealers often flocked for picking mattresses. Identifying such dealers fast, and accurately, made it possible for the company to penalise the weak spots. A serial number could be tampered with but not a RFID tag. The source and destination were all easy to read on the dashboard.

Bugs out, Fruits in – RFID bolsters the brand

With easily deployed and smoothly-administered RFID tags punctuating all nooks and corners of the entire chain, now there was no room for malafide elements to hide in. Now authenticity came easily as RFID was used for material placement, movement and tracking. This technology also ensured that the product shipped in the utmost quality, transparency and reliability levels.

The impact on sales was manifested in a spike of 10 per cent. To add to that, there was considerable jump in dealer confidence. Authorised dealers also found it easy to retain their margins now as unscrupulous competition was out of the market. There was a rise in exclusivity too – to the tune of 40 to 50 per cent.

Plus, the company could now stream its products across the chain – from factory to retail stores passing all distribution points- faster and with better control. Also, any defect was captured and monitored spot-on. The inventory levels, productivity at the shop floor, rack positions and product movement – everything was reaping the benefits that RFID data armed the company with.

The beauty of this solution was that it was not intrusive or loud. It sat silently, doing its job and arming everyone with real-time data.

Like ants – moving noiselessly but adding to the tree, just like a good chain should.