Reconciliation is complex – when there are two different, and large-scale, organizations trying to shrink the gaps of data formats and process differences. But should it be complicated?

Supply chains across manufacturing businesses are becoming more global and increasingly complex. Modern businesses need smarter financial and supply chain management solutions that are resilient and scalable to meet changing customer needs. But most importantly, such solutions help build trust between businesses and customers.

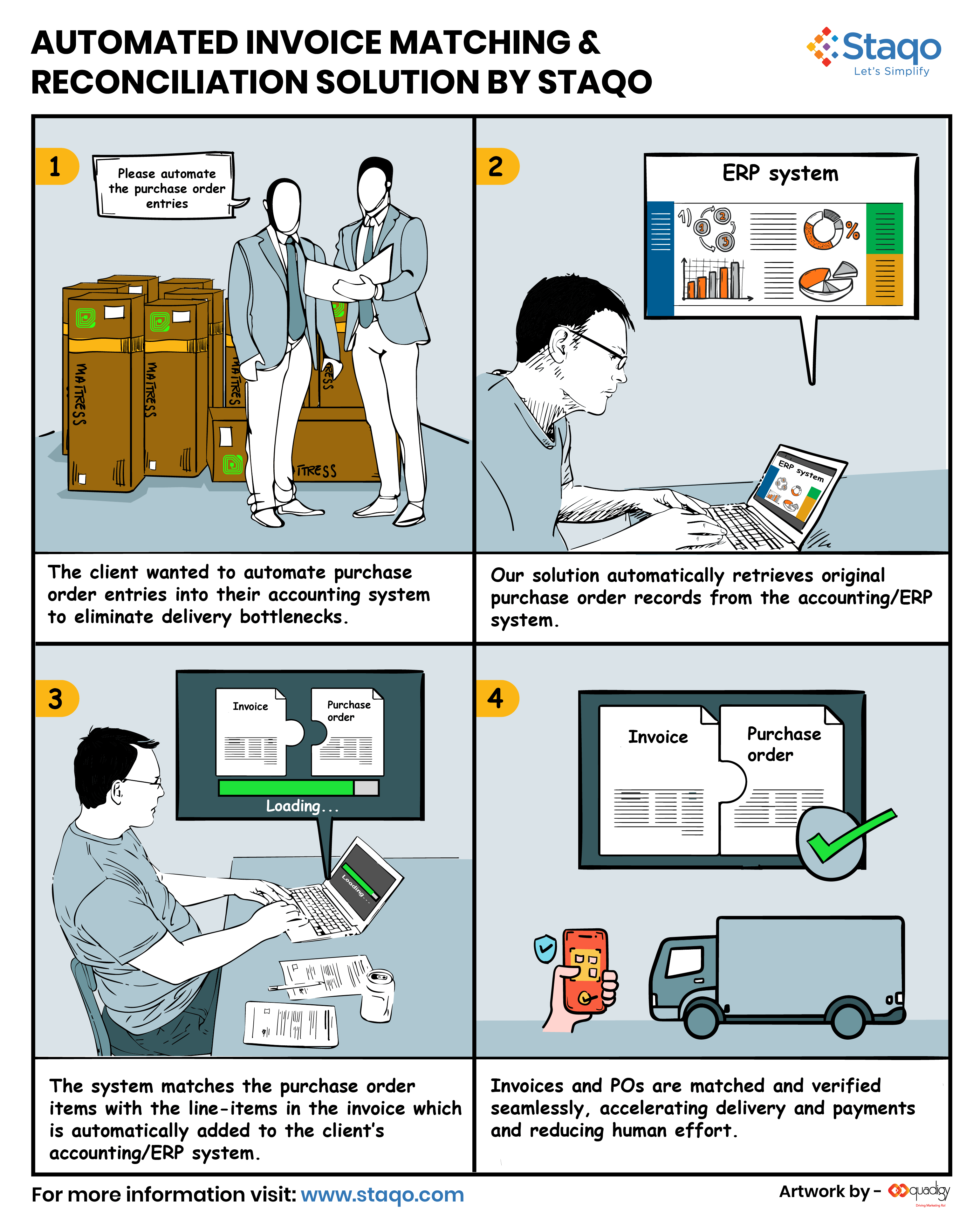

Staqo is an IT partner to Australia’s premier polyurethane foam manufacturing company, which in turn is a major supplier of foam for a Texas, US-based brand of mattresses. When it received a big list of 3000 purchase orders raised by the US company, the Australian firm faced a major challenge in terms of verifying that the invoices presented against purchase orders precisely match the cited purchase order. Until now, teams at Staqo’s client and the US-based mattress company had to manually match and reconcile the presented invoices against the cited purchase order – a task that was laborious, expensive, and prone to errors. Therefore, Staqo’s client needed a solution that would minimize human effort, eliminate manual documentation, and prevent expensive delays.

Staqo was tasked with building a solution to align the processes of the customer’s purchasing department and the vendor team of the supplier. This solution would integrate both the organizations’ processes in such a way that the Purchase Order in the customer system could be converted to a Sales Order, seamlessly and with minimum effort. To achieve this, Staqo worked to develop a system which would sync purchase and invoice slips effectively so that price changes could be updated immediately and, as a result, financial reconciliation could be smoother and more efficient.

First, the team categorized and outlined all the file formats and all the expected data that had to be transferred between the two businesses. It identified all the key stakeholders – business users and key users of the systems. The development teams began their part of the project. They had to build a system that worked as per the overall idea of alignment. Then a test team was incorporated to ensure that the test plans and deliverables were in line with scope and priorities defined in the project.

All the necessary changes and components were integrated to automate sections of the trading processes between the Australian company and its US client firm. While new interfaces worked to provide efficiency and accuracy of data that would pass between the two organizations; any redundant areas that interfered in the process were also removed.

A smart and intuitive interface

Staqo created a system that was least intrusive to users and decision-makers. Its task was to support the purchase and sales teams in their jobs with real-time information in a uniform format. The new Electronic Data Interchange (EDI) system, therefore, worked as a translator between Staqo’s client and the US firm with a newly-designed interface, through which the US company would electronically receive an invoice. The system would match the invoice with the relevant purchase order and the US company could then initiate a payment in no time.

The intuitive and automated system worked in the background, enabling users to share information easily while also supplying them with data that was more accurate, cleaner, and unambiguous.

The system began delivering better results soon after its implementation and both the companies saw the transformation that they had envisaged with this integration. Some of these benefits included:

- Massive reduction in manual effort expended by both the businesses

- Considerable automation of the purchasing process at the US firm as well as the sales process at the Australian PU foam company

- Increased efficiency that was driven by less manual entry of data

- Augmented levels of accuracy

- Significant reduction in workload for both the companies

But above all, the integration was achieved with minimal disruption to both the businesses. Key implementation parts of the project were undertaken after normal business hours. Each business was empowered with the means and timelines for implementing the interface and required changes to their own systems.

Further, the Purchaser team at the US mattress company and the Vendor team at the Australian firm were also better aligned as a result. The ability to match POs to invoices significantly streamlined the invoice approval process for the accounts payable department and eliminated the need to make paper-based and manual accounting entries, thus reducing costs and shortening cycle times.

With the new automated accounts payable system, the Purchase order could be entered and approved within a single process, and in the next process, the purchase order line-items would be matched and verified with the line-items from the received invoice. Following this, a delivery docket with a bar code would be generated and attached with the confirmation of delivery with quantity which would be signed and scanned. The delivery details would be easily loaded from the file.

As a result, the entire delivery and financial reconciliation process was fast-tracked, as delays and overlaps that had previously encumbered the teams and systems with time and cost overruns, were now entirely eliminated. The new system led to greater accuracy, standardization, and more accurate decision-making, benefitting both companies and strengthening their collaboration in the long term.